Simple work

MoTIS® FLS GLASS is a modern and innovative solution for Pick-By-Vision applications. Whether in the classic picking warehouse, or in production logistics MoTIS® FLS GLASS enables flexible and effective work.

The employee only needs a pair of InnoLOG® certified data glasses, which are connected to the MoTIS® booking server via WLAN. User inputs can be made via the touch surface of the data glasses themselves, via voice input, the integrated camera, external barcode scanners, mobile keyboard or RFID readers. MoTIS® presents the warehouse coordinates to the employee in a large and clear manner on the display of the glasses - without the need for hands. In this way, he recognizes what needs to be done next much faster than on conservative pick lists or handheld terminals. MoTIS® guides the employee to the target storage location in a path-optimized manner. There he confirms, e.g. via voice control by speaking a check digit, that he has reached the correct storage location. Alternatively, he can also read a barcode with a pistol or ring finger scanner.

MoTIS® FLS GLASS enables virtually error-free work due to consistent user guidance and space and article control.

Low costs Highest flexibility

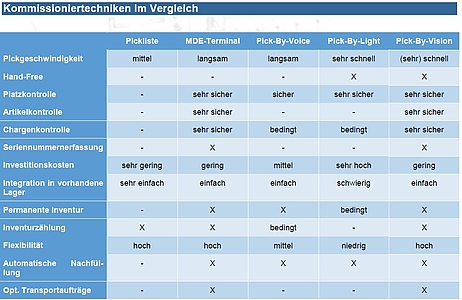

MoTIS® FLS GLASS can be easily integrated into existing warehouse and picking systems without large investments. Existing pick lists can be imported into MoTIS® via simple data interfaces. MoTIS® optimizes the pick orders and then processes them online via the data glasses. MoTIS® FLS GLASS enables extremely fast and productive hand-free working, similar to Pick-By-Light. However, MoTIS® FLS GLASS has three decisive advantages:

1. the required investment volume is very low. Conventional, usually existing racking systems can be used. Thus, the costs remain within limits. Articles, assortment and warehouse layout can be taken over immediately and without changes-.

2. with MoTIS® FLS GLASS performance peaks in order picking can be handled easily. A second or third employee can be used for picking in a picking zone at any time without any problems.

3. the picking zones can be easily adjusted during the running process. In this way, employees and resources can be used optimally.

The work and the bookings with MoTIS® FLS GLASS are controlled and monitored via the MoTIS® booking server. Thus, the bookings can be made online in real time, indispensable for all requirements of modern warehousing, such as permanent inventory. In addition, just like the MoTIS® Android Client for radio terminal, MoTIS® FLS GLASS can also work semi-autonomously. If no WLAN connection is available temporarily, MoTIS® temporarily stores the bookings on the data glasses. As soon as a network connection is available again, the MoTIS® FLS GLASS client automatically reconnects to the booking server and transfers the data. Thus, MoTIS® FLS GLASS is clearly superior to classic radio and pure voice systems in flexibility, user-friendliness and effectiveness.

![[Translate to English:] MoTIS® FLS GLASS](/fileadmin/_processed_/6/7/csm_InnoLOG_MoTIS-FLS-GLASS-dt_7445f9c373.png)