MoTIS® DC efficiently takes over and optimizes all relevant picking processes

Picking performance is greatly improved by order optimization. An intelligent strategy shortens the walking distances of the individual pickers and significantly increases the picking quality. MoTIS® DC processes complex goods receipts, which are taken over from an ERP system or also entered directly in MoTIS® DC, efficiently and quickly. To support the internal entry, MoTIS® DC provides order suggestions based on minimum stocks, range of coverage analyses and historical data. Extensive functions, e.g. quality lock, pallet management, printing of entry and goods accompanying documents, scanning of barcode and RFID, guarantee a fast, secure and transparent process.

For optimal storage location determination, MoTIS® WMS warehouse control and management draws on, among other things, ABC classification, cross docking, minimum stock levels, FIFO, stock distribution, etc.

With MoTIS® DC, picking becomes faster, safer and cheaper.

MoTIS® DC optimizes multi-level and parallel order processing via pick lists, via mobile handheld terminals with barcode/RFID scanner, via Pick-By-Light/Pick-By-Voice and via the MoTIS® FLS radio guidance system. MoTIS® DC always selects the best strategy and thus reduces distribution costs

MoTIS® MFC material flow computer optimally controls automated picking systems in combination with MoTIS® DC. Due to the seamless integration into MoTIS® , interfaces are omitted - goods and data flow are fast, transparent and cost-efficient.

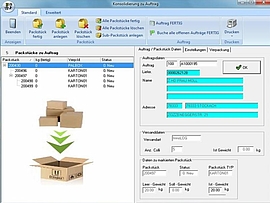

Efficient goods and transport handling through consolidation as part of MoTIS® DC

MoTIS® DC Consolidation assembles goods shipments cost-minimized and defines the package contents. If required, MoTIS® DC creates all necessary shipping documents, transfers the shipment data electronically and tracks the shipments to the end customer (fulfillment). Seamless integration of warehouse control, package optimization, material flow control, picking and shipping minimizes throughput times, picking errors and shipping costs.

MoTIS® DC

Distribution CenterYour advantages

- Cost savings through optimal use of employees and technology

- Complex incoming goods

- Package optimization

- Volume calculation

- Shipping costs optimization

- Forwarding discounts through own routing labels

- Seamless product tracking

- Fulflillment & e.Fullfillment

- Crossdocking

- Shipment consolidation in one system

- Transfer of shipping lists via EDI, etc...

Performance overview

- Complex goods receipts

- Returns handling

- Optimal storage space allocation

- Order entry

- Work preparation

- Compilation of picking orders from customer orders

- Picking optimization

- Multi-level picking

- Multi-batch picking

- Consolidation

- Batch management (EU 178/2002)

- Serial number management

- Barcode, RFID, Transponder

- Pick-By-Light

- Pick-By-Voice

- Completeness control

- Weighing control

- Package management

- Volume calculation

- Package optimization

- Minimization of shipping costs (least-cost)

- Delivery documents, content lists

- Individual labeling (fulfillment)

- Electronic data transfer to forwarders, carriers and CEP services. (DFÜ / EDI)

- Shipment tracking